Quality In Every Step

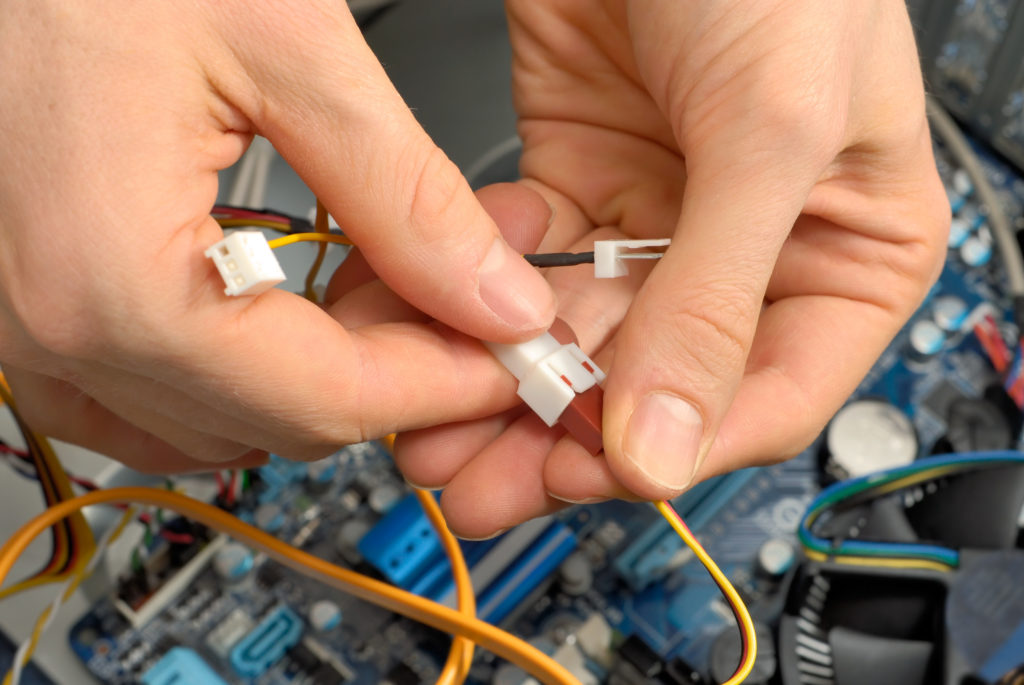

The highest quality product is our top priority. We have established processes throughout the entire system to bring high-quality products to you. These are some of the steps we take to make sure this happens:

- Incoming Inspection: Components and finished goods are all inspected during the receiving process. New components and specialized parts also require additional QC inspection and approval.

- Operator training: Training is required annually for all employees. Employees are all trained and/or familiar with WHMA A-620 training, which is used in our manufacturing process. Our operators receive ongoing training on operating machines, soldering, crimp quality, and new products.

- Detailed Work Instructions: All products are set up with a detailed assembly traveler with instructions on all steps, tools, and tests needed to build it the same every time.

- 100% Continuity Testing: Products are all tested for continuity after assembly is completed. Hi-pot testing can also be performed when required.

- Crimp Quality Monitoring: Crimp heights and dimensions are inspected and recorded every time a new applicator is set up or a new job is started. Our terminal presses also have crimp force monitors to automatically stop the machine when crimps are out of tolerance.

- First Article Approval Process: Casco has a detailed First Article Inspection Plan that we use for all new assemblies and harnesses. This plan involves the detailing and recording of every step to make the part. The customer will receive a form to sign off that the part meets their requirements. Custom First Article plans can be set up to meet the individual customers requirements.

- ROHS: Casco uses ROHS products with all components and assemblies whenever it is applicable.

- Product Traceability: All product manufactured by Casco is identified with a unique code that links it back to the order. This information allows for us to trace back to all details involved while making that part.

- In Process Auditing: Inspections are done throughout the process on all steps during the manufacturing process. These inspection results are recorded on QC traveler as they are completed.

- Pull testing: Pull testing is performed and recorded when needed to test parts or tooling.

- Detailed Visual Inspection: Guidelines have been established for detailed visual inspection on all parts. Additional visual inspections are often added to the travelers/QC worksheets for parts that need custom inspections.

Quality Policy

Casco Manufacturing Company strives to achieve the highest level of service, quality, and responsiveness in the manufacturing and selling of custom cable assemblies and wire harnesses. To achieve these goals we:

- Are sensitive to our customers needs, both internal and external customers.

- Provide on-going employee training to enhance the quality of our products and services.

- Build quality products with zero defects to reduce costs, improve efficiencies, and increase customer satisfaction.

- Promote all employees to contribute to the quality improvement process.

The entire Casco Manufacturing Co. team supports the spirit and intent of our quality policy. We will aggressively strive to ensure that customer satisfaction is achieved at all times.