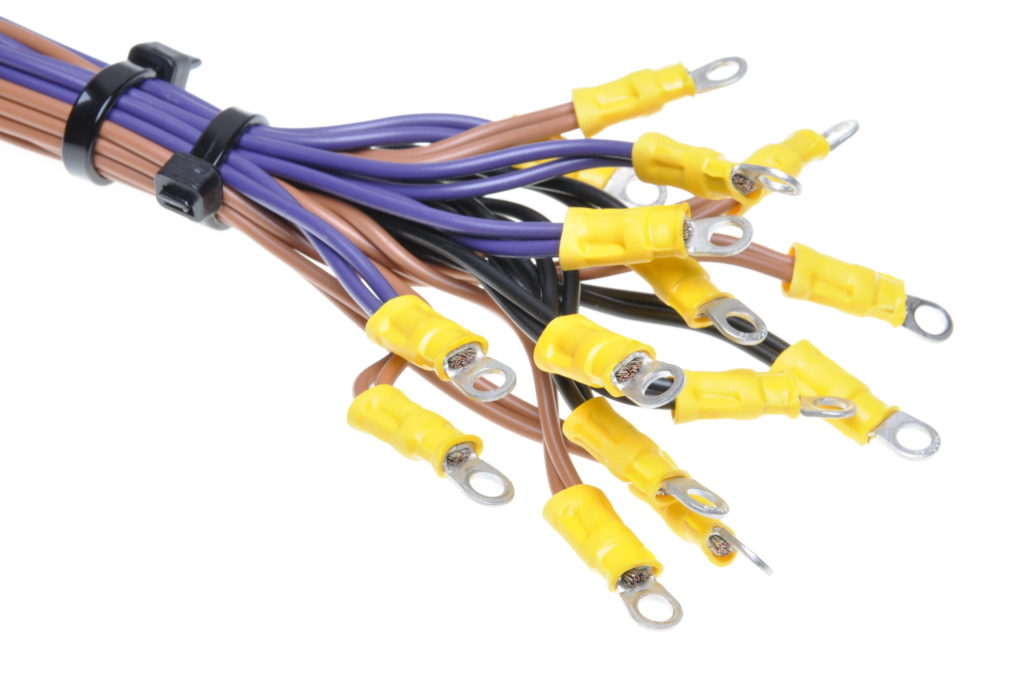

Casco will cut, strip and terminate your ground cables to match your exact requirements. We can build various cable sizes to meet your specific need. Cables range from 2 AWG to 28 AWG.

- Battery cables

- Braided rope ground straps and assemblies

- Bare copper and tin copper options

- Solder dipping and tinning available

- Terminated with ring, fork, spade, or your choice of terminal

- Insulated and uninsulated terminal options

- Custom labeling and marking

- Custom Lengths