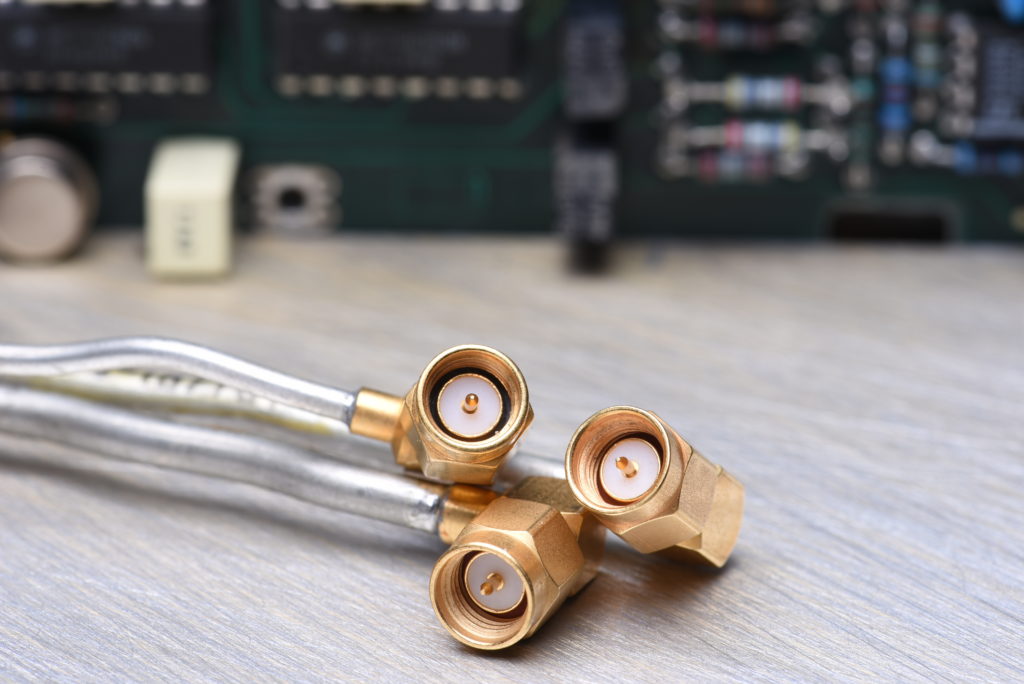

Noted for its wide bandwidth and low susceptibility to interference, coax cables, as well as RF cable assemblies, are commonly used for data communications. Even though one coaxial cable assembly will appear to be virtually identical to the next, rarely is that the case. Trade designations generally refer to the cable’s electrical characteristics; specifically the impedance of the cable.

Coax cable types (RG142, RG400, etc.) should not be mixed – they have differing levels of impedance and mixing them may degrade system performance. Equally important is the quality of the cable itself. A poorly manufactured cable can ruin the transmission, too. Casco takes all this into consideration when manufacturing coaxial cable assemblies and delivers only finished product that meets your exact specifications and our exact quality standards.

- Automated cable stripping for precise, high-quality terminations.

- Machine crimp for consistent terminations

- Coaxial cable assemblies are made to meet your exact length

- Custom bundling of cables is available

- Right angle style connectors available

- Custom labels available

- Bundling of multiple cables and multi-conductor coaxial cable