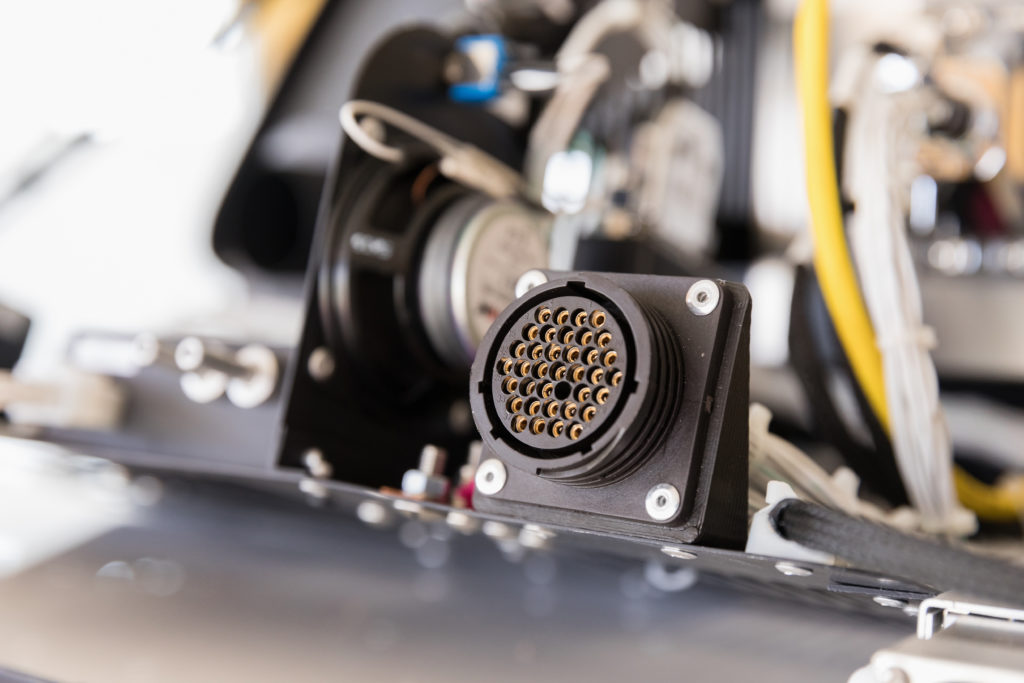

Casco is skilled and highly experienced in manufacturing all types of cable and wire harness assemblies with circular style connectors. These cables are rugged, dependable and meet high signal integrity. We can use military or commercial style connectors. Casco will build your cable and wire harness assemblies to match your exact requirements.

- Weathertight and MIL Spec options available

- Circular cable and wire harness assemblies with the highest quality and reliability

- Casco works with lots of manufacturers including: Amphenol, ITT Canon, Glenair, Lapp, Lemo, Souriau, Switchcraft, Sealcon and Neutrik

Applications of Circular Power Cable and Custom Wire Harness Assemblies

The shape of circular power connectors makes them uniquely robust and resilient against physical and environmental hazards. Because the waterproof connector is shaped as a circle, it features a higher strength-to-weight ratio than connectors of other shapes. Combined with the threaded, screw-in connection many of these provide, circular power cable and wire harness assembliestend to stay connected even when acted on by outside forces.

Circular connectors for power supply cables are used frequently in applications where strong, stable connections are not only preferred, but essential. The security and reliability of these high-performance cable assemblies make them staples of numerous industries. For example, they can be found in automated robotic assembly systems in the manufacturing and Military sector. They’re also used often in vehicles where electrical systems may be subjected to lots of jostling and bumping. Medical equipment uses a circular cable assembly because it ensures dependable power to life-saving machines and devices.

Why Choose Casco Manufacturing for Heavy-Duty and Military Grade Circular Assemblies?

We’re dedicated to providing the highest levels of quality in everything we do. This begins with the extensive IPC 620 training our employees go through every 2 years, providing them with all the skills and expertise they need to ensure the best possible results from our manufacturing processes. All products are subjected to comprehensive continuity testing after manufacturing to make sure they deliver the level of performance and dependability our customers need from us. We also perform in-process auditing throughout the manufacture of our products and record the results in case we need to go back and examine the root cause of any failures.

Our cables are designed to meet stringent military and commercial standards for quality and performance. This means our customers can expect exceptional signal integrity, ruggedness and reliability from our products. The team here at Casco works closely with customers to develop custom-built solutions that are tailored to their exact requirements. We also partner with leading connector manufacturers including Amphenol, ITT Cannon, Glenair and Lemo, giving our products the best technology available in the industry. Our goal is always to provide the perfect fit for any application and situation.

We never stop working to improve what we offer, and our customers know it. Building long-lasting relationships with our clients is one of our top priorities, and that means providing them with peace of mind in critical applications where failure is not an option. To learn more about everything we can do for you, reach out and talk to one of our representatives today.