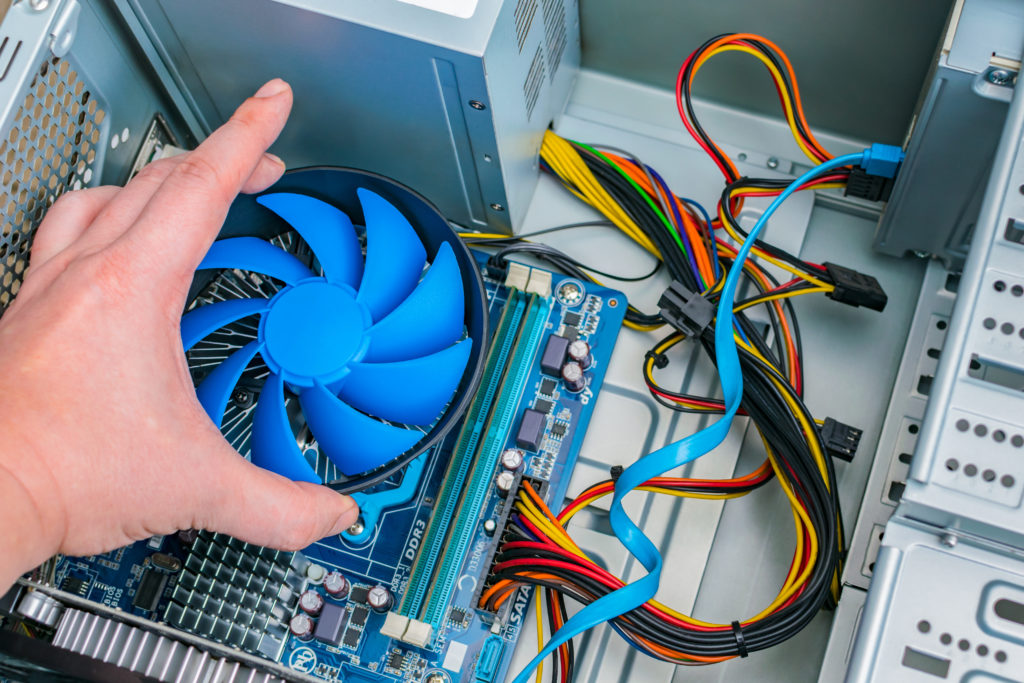

Box Build

Casco has the ability to assemble and test your complete box build assembly. There are many benefits of outsourcing your complete box build:

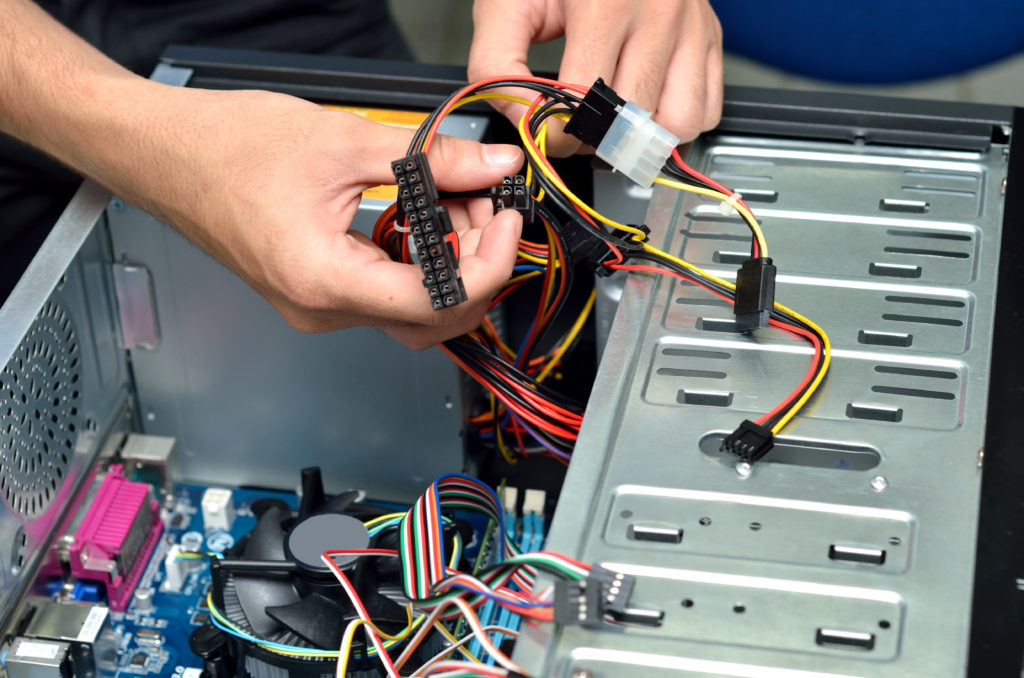

- Reduce Suppliers: Casco can build all the cable assemblies, harnesses, din rail units to customize your box build

- Reduce cost: Get more of your products built together, avoiding multiple marks up from multiple suppliers.

- Improve quality: Box builds will arrive at your facility ready to install. They will be assembled and fully tested when they arrive.

- Improve lead times: Casco will work with you to plan shorter lead times. We can build sub-assemblies and stock components for quick turnaround and easy changes.